KEWEI Water Glass Investment Casting Process

Cost-Effective Precision for Complex Components

Discover KEWEI’S Water Glass Investment Casting Process—Rapid Shell Moulding, Eco-Friendly & High-Volume Ready. Request A Free Technical Guide Now!

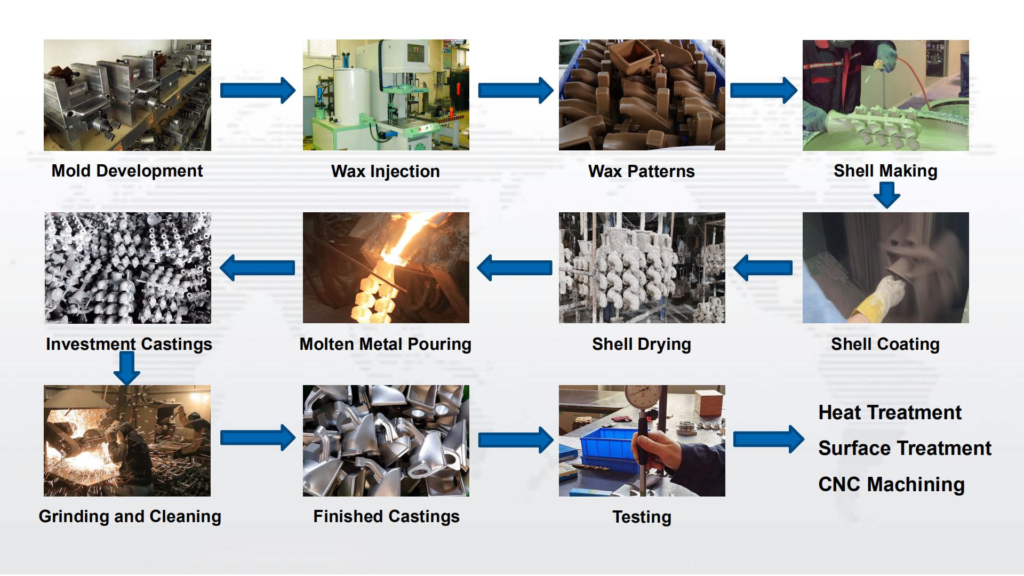

The water glass investment casting process (sodium silicate process) is a cost-efficient method widely used for producing intricate metal components in industries like automotive, energy, and general engineering. KEWEI, a global ISO 9001-certified leader in foundry solutions, optimizes this traditional technique with modern automation and material innovations. This article explores how KEWEI’s casting process delivers precision, scalability, and 30% lower production costs compared to ceramic shell methods.

1. What is the Water Glass Investment Casting Process?

The water glass process uses sodium silicate binder to create refractory shell molds around wax patterns. KEWEI enhances this method with:

- Fast Cycle Times: Shell hardening in 15–30 minutes via CO2 gas curing.

- Material Savings: 40% lower binder costs vs. ceramic slurries.

- ECO Compliance: Water-based, low-VOC materials meet REACH standards.

Related Keywords: sodium silicate casting process, eco-friendly shell moulding

2. KEWEI’s Innovations in Water Glass Process

A. Advanced Shell Formulations

- High-Strength Mixes: Alumina-silica blends withstand 1300°C for steel and iron castings.

- Nano-Modified Binders: Reduce surface roughness to Ra 6.3–12.5μm for minimal post-processing.

B. Smart Automation

- Robotic Dipping Systems: Ensure uniform shell thickness (±0.2mm) across complex geometries.

- AI-Optimized CO2 Curing: Adjust gas flow rates for consistent mold hardness.

Case Study: An automotive supplier cut per-unit costs by 28% using KEWEI’s water glass process for aluminum pump housings.

Related Keywords: automated sodium silicate casting, water glass shell equipment

3. Key Advantages of KEWEI’s Water Glass Process

- Cost Efficiency: 50% lower CAPEX vs. ceramic shell lines.

- Rapid Production: Produce 500–1000 shells/day for high-volume orders.

- Material Versatility: Ideal for carbon steel, ductile iron, and non-ferrous alloys.

Related Keywords: low-cost investment casting, high-volume shell moulding

4. Industry Applications

- Automotive: Engine brackets, transmission parts (IATF 16949 compliant).

- Energy: Valve bodies and pipe fittings for oil & gas (API 6A).

- General Engineering: Pump housings, hydraulic components.

Related Keywords: water glass casting for automotive, industrial sodium silicate moulding

5. Overcoming Traditional Limitations

- Poor Surface Finish? KEWEI’s nano-coated shells achieve Ra <12.5μm.

- Low Mold Strength? Reinforced with zirconia additives for high-temperature stability.

- Slow Curing? CO2 gas injection completes hardening in <30 minutes.

Related Keywords: water glass casting defects, sodium silicate process optimization

6. Partnering with KEWEI: End-to-End Support

Choosing KEWEI unlocks:

- Free Process Audit: Optimize your current water glass workflow.

- Turnkey Equipment: From wax injectors to CO2 curing chambers.

- Global Compliance: CE, RoHS, and ISO 9001 certifications for export-ready solutions.

Related Keywords: water glass investment casting supplier, foundry equipment solutions

Conclusion

The KEWEI water glass investment casting process bridges affordability and precision, making it ideal for high-volume, geometrically complex components. With 15+ years of expertise, smart automation, and eco-conscious materials, KEWEI empowers manufacturers to compete globally without compromising quality or sustainability.

Ready to Revolutionize Your Casting Process?

Contact KEWEI Today for a Free Sample Casting!