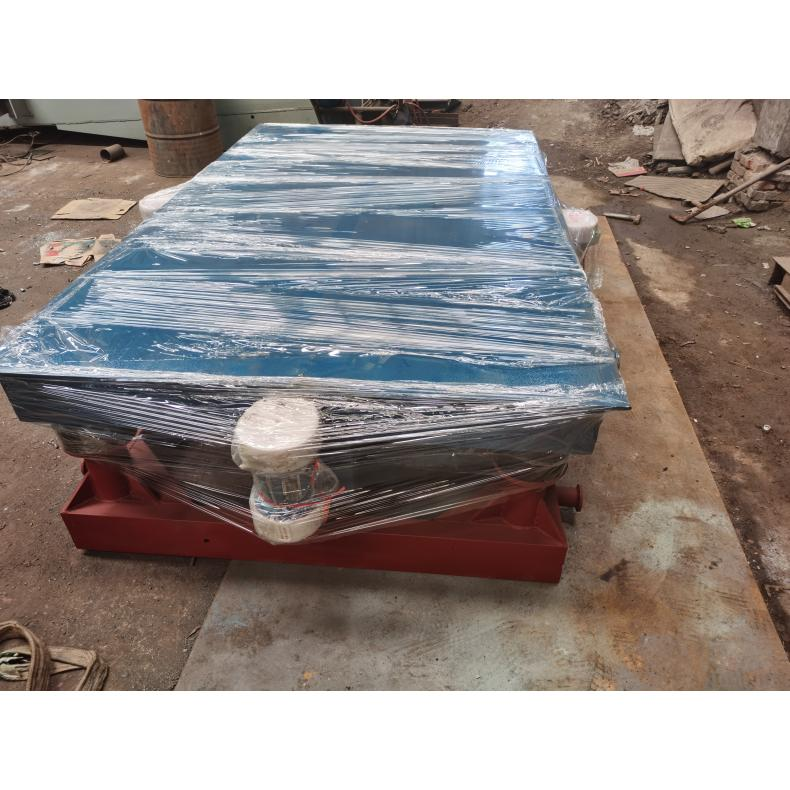

Casting Machine Vibrating Table

A vibration compaction table (Casting Machine Vibrating Table)is a specialized piece of equipment designed to compact sand molds effectively. It operates using vibration motors as excitation sources, which are installed in pairs or symmetrically to function in reverse synchronization.

For single-axis compaction tables, one pair or set of excitation sources generates vibration forces along the Z-axis. In contrast, three-axis vibration compaction tables are equipped with three pairs or sets of excitation sources, enabling vibration forces in three directions (X, Y, and Z).

This multidirectional vibration ensures thorough compaction of the sand mold with specific acceleration, improving density and uniformity.

The table features a pneumatic clamping device for securely and flexibly holding the sand mold in place, enabling quick adjustments. This ensures the mold cavity and surrounding areas are thoroughly filled with sand, compacting the grains within and achieving a required degree of rigidity under negative pressure conditions. Such compaction supports smooth and efficient casting processes.

Moreover, vibration compaction tables (Casting Machine Vibrating Table)offer customization options, including airbags, rubber composite springs, fixed or mobile configurations, and either power or variable frequency drives. These features enhance the table’s adaptability to various operational requirements and casting environments.

Technical Specifications

| Type | Vibration direction | Excitation force(KN) | Power(kw) |

| DZK20 | Z | 20 | 1.5 |

| DZK30 | Z | 30 | 2.2 |

| SZK50 | X、Y、Z | 50 | 3.7 |

| SZK80 | X、Y、Z | 80 | 6 |

| SZK100 | X、Y、Z | 100 | 7.4 |

| SZK160 | X、Y、Z | 160 | 11.8 |

Kewei’s v-process casting line advantages

- High Precision: Achieves exceptional accuracy in casting, ensuring that components meet stringent specifications.

- Excellent Surface Quality: Delivers superior surface finishes, reducing the need for additional processing.

- Environmental Sustainability: Operates with no emissions or waste, making it an eco-friendly choice in metal casting.

Key Procedural Steps in v-process casting

The lost foam casting (LFC) process is a precision casting method that uses expendable foam patterns to create complex metal parts. Below is a structured breakdown of the process based on your source material, along with key considerations and applications:

1. Pattern Material Selection

- Aluminum Die Castings:

Use expandable polystyrene (EPS) with pentane as a blowing agent.

Why: EPS is lightweight and decomposes cleanly at aluminum’s lower melting point (~660°C). - Cast Iron/Steel Parts:

Use a copolymer of EPS and EPMMA (expanded polymethyl methacrylate).

Why: The copolymer withstands higher temperatures (iron: ~1,200–1,500°C; steel: ~1,370–1,500°C) and reduces residue.

2. Pre-Expansion

- Process:

EPS beads are pre-expanded in a fluidized bed dryer using pentane (a volatile hydrocarbon).

Purpose: Increases bead size (typically 20–50x) to achieve target density (e.g., 20–30 kg/m³). - Key Control: Temperature and residence time to ensure uniform expansion.

3. Molding

- Tooling: Pre-expanded beads are blown into a metallic permanent mold using compressed air.

- Bonding: Heated (100–120°C) to fuse beads via steam, forming the foam pattern geometry.

- Pattern Design: Complex geometries are split into sections for easier molding, then assembled post-foaming.

4. Pattern Assembly & Gating

- Cluster Assembly:

Multiple foam patterns are mounted onto a gating system (typically EPS) to form a cluster.

Purpose: Enables simultaneous casting of multiple parts in one pour. - Gating Design: Channels must optimize molten metal flow and minimize turbulence.

5. Coating Application

- Refractory Coating:

Clusters are dipped in a water-based ceramic slurry (e.g., alumina, zirconia) to form a 2 mm coating.

Functions:- Prevents sand erosion during pouring.

- Creates a barrier to reduce gas defects from decomposing foam.

- Enhances surface finish.

- Drying: Coated clusters are dried thoroughly to avoid steam explosions during casting.

6. Mold Preparation

- Sand Compaction:

Coated clusters are placed in a flask, surrounded by unbonded quartz sand (grain size 0.1–0.4 mm).- Sand Raining Feeder: Ensures even distribution.

- Vibrating Table: Compacts sand to 90–95% density for stability.

- Sprue Exposure: Only the gating system’s sprue remains exposed for metal pouring.

7. Casting

- Pouring:

Molten metal is poured into the sprue. The heat decomposes the foam (EPS vaporizes; copolymer may leave minor ash).- Metal Flow: Fills the mold cavity precisely, replicating the foam pattern.

- Gas Management: Decomposition gases (pentane, styrene) vent through the permeable coating and sand.

- Critical Factors:

- Pouring temperature and speed to avoid turbulence.

- Foam degradation rate must match metal front advancement.

8. Demolding & Post-Processing

- Solidification: Metal cools in the sand mold (time depends on part size and alloy).

- Shakeout: Sand is removed via vibration, revealing the casting cluster.

- Cutting: Individual castings are separated from the gating system (e.g., sawing, grinding).

9. Sand Recycling

- Reclamation:

Used sand is cleaned (screening, thermal reclamation) to remove debris and residual coating.

Benefits:- Reduces material costs by 90–95%.

- Environmentally sustainable (minimal waste).

Key Advantages of Lost Foam Casting

- Complex Geometries: No cores or draft angles needed (e.g., engine blocks, pump housings).

- Dimensional Accuracy: ±0.3 mm tolerance achievable.

- Surface Finish: 3–6 μm Ra (reduces machining).

- Cost-Effective: Low tooling costs for prototypes/small batches.

Common Applications

- Automotive: Cylinder heads, intake manifolds.

- Industrial Valves/Pumps: Internal passages cast in one piece.

- Art/Decorative Castings: Intricate details preserved.

Challenges & Mitigation

| Issue | Solution |

|---|---|

| Gas porosity | Optimize coating permeability |

| Incomplete filling | Adjust foam density/pouring speed |

| Sand collapse | Improve compaction vibration settings |

This process is ideal for industries prioritizing complex designs, reduced machining, and sustainability. Let me know if you need further details on specific steps!

Features of V-process casting

- High Casting Quality at Low Cost:

The process delivers excellent casting quality while maintaining cost-effectiveness. - Material Versatility:

There are no significant material limitations, allowing for a range of suitable sizes. - Precision and Surface Finish:

Achieves high precision and a smooth surface finish, reducing the need for extensive cleaning and saving on machining time. - Reduced Internal Defects:

Significantly minimizes internal defects, resulting in a compact casting structure. - Large-Scale Mass Production:

Capable of supporting large-scale and mass production of components. - Ideal for Repeated Castings:

Particularly suitable for the mass production of identical castings. - Flexible Operation:

Adaptable for both manual operation and automated production line control. - Environmental Compliance:

The production line’s operational status meets environmental protection technical parameters. - Improved Working Conditions:

Enhances the working environment and production conditions in the casting line, reducing labor intensity and energy consumption.

These features collectively position lost foam casting as a highly efficient and sustainable option in the manufacturing of complex castings.