Investment Casting & Machining Machines

In precision manufacturing, the synergy between investment casting and machining machines eliminates bottlenecks, reduces costs, and accelerates time-to-market. KEWEI, a global leader in integrated foundry solutions, pioneers end-to-end systems that combine high-precision casting with CNC machining—delivering aerospace, automotive, and medical components ready for assembly. Discover how KEWEI’s unified workflow redefines efficiency and quality.

1. The Power of Integrated Casting & Machining

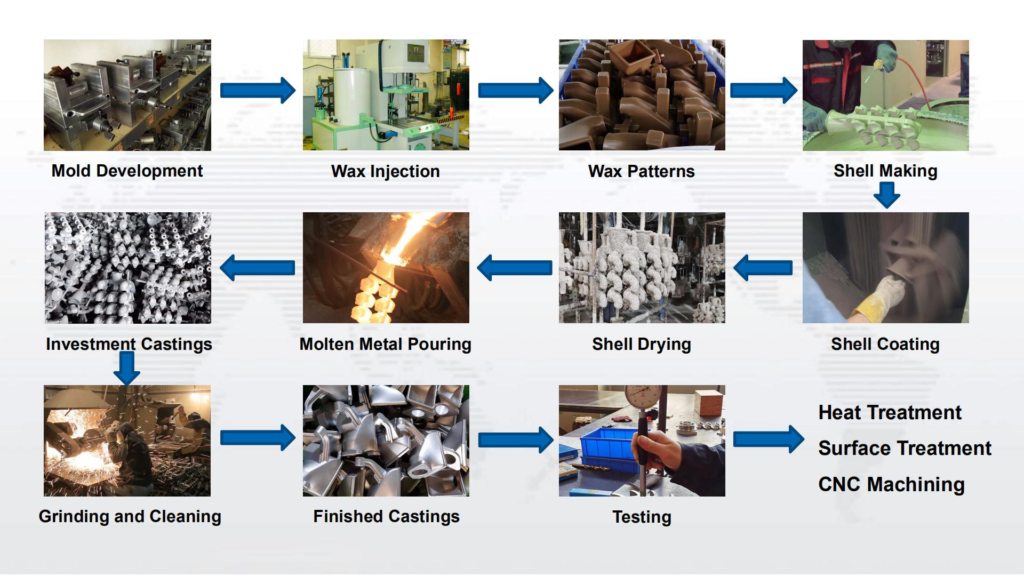

KEWEI’s investment casting and machining machines bridge the gap between molten metal and finished parts:

- Single-Workflow Precision: Cast near-net-shape parts, then machine critical features (e.g., threads, bores) in one setup.

- Material Savings: Reduce raw material waste by 30-50% vs. traditional subtractive methods.

- Zero Handling Errors: Eliminate alignment issues between casting and machining stages.

Related Keywords: integrated casting and milling, precision casting with CNC

2. KEWEI’s Core Technology Innovations

A. Hybrid Casting-Machining Cells

- AI-Driven Process Control: Adaptive algorithms adjust casting parameters (pouring speed, cooling rate) based on final machining requirements.

- Multi-Axis CNC Integration: 5-axis machining centers achieve ±0.01mm tolerances post-casting.

B. Smart Material Optimization

- Alloy-Specific Workflows: Tailored for aluminum (EV components), titanium (medical implants), and Inconel (aerospace).

- In-Process Quality Control: On-machine CMM probes verify dimensions during machining.

Case Study: An aerospace client cut lead time by 45% and scrap by 28% using KEWEI’s integrated cell for turbine blade production.

Related Keywords: KEWEI hybrid manufacturing, casting-to-machining automation

3. Industry-Specific Applications

- Aerospace: Cast and machine turbine blades with internal cooling channels (AMS 2175 compliant).

- Medical: Produce FDA-approved titanium implants with Ra <0.4μm surface finish.

- Automotive: High-volume aluminum EV motor housings with integrated mounting features.

Related Keywords: precision casting with CNC finishing, multi-process manufacturing

4. Overcoming Hybrid Production Challenges

- Thermal Distortion? KEWEI’s AI predicts and compensates for casting shrinkage during machining.

- Tool Wear? Smart lubrication systems extend tool life by 40%.

- High Capital Costs? Modular systems scale from prototyping to mass production.

Related Keywords: hybrid manufacturing defects, integrated foundry ROI

5. Partnering with KEWEI: Beyond Equipment

Choosing KEWEI unlocks:

- Free Process Simulation: Digital twin modeling for cycle time and cost optimization.

- Unified Software Suite: Seamless data flow from CAD/CAM to casting and CNC machines.

- Global Compliance: Machines meet AS9100 (aerospace), ISO 13485 (medical), and CE standards.

Related Keywords: investment casting and machining solutions, turnkey hybrid systems

Conclusion

In an era where agility and precision are paramount, KEWEI investment casting and machining machines deliver a revolutionary leap—transforming raw metal into finished components with unmatched speed and accuracy. With 15+ years of cross-industry expertise, smart factory integration, and a relentless focus on ROI, KEWEI empowers manufacturers to dominate competitive markets.

Ready to Unify Your Workflow?

Contact KEWEI for a Free Hybrid Cell Demo Today!