Your Trusted Global Investment Casting Equipments Supplier

In the competitive landscape of precision manufacturing, choosing the right investment casting equipment supplier is pivotal to achieving quality, efficiency, and scalability. KEWEI, a global ISO 9001 and AS9100-certified supplier, stands as a leader in delivering end-to-end foundry solutions for aerospace, automotive, and medical industries. With 20+ years of expertise, vertically integrated production, and a client-centric approach, KEWEI empowers manufacturers worldwide to transform raw materials into high-value components—faster, smarter, and more cost-effectively.

1. Why KEWEI is the Preferred Investment Casting Equipments Supplier

A. End-to-End Solutions

- Full Process Coverage: From 3D wax printers (45�–45K–120K) to 5-axis CNC finishers (85�–85K–300K), KEWEI supplies every machine needed for a seamless workflow.

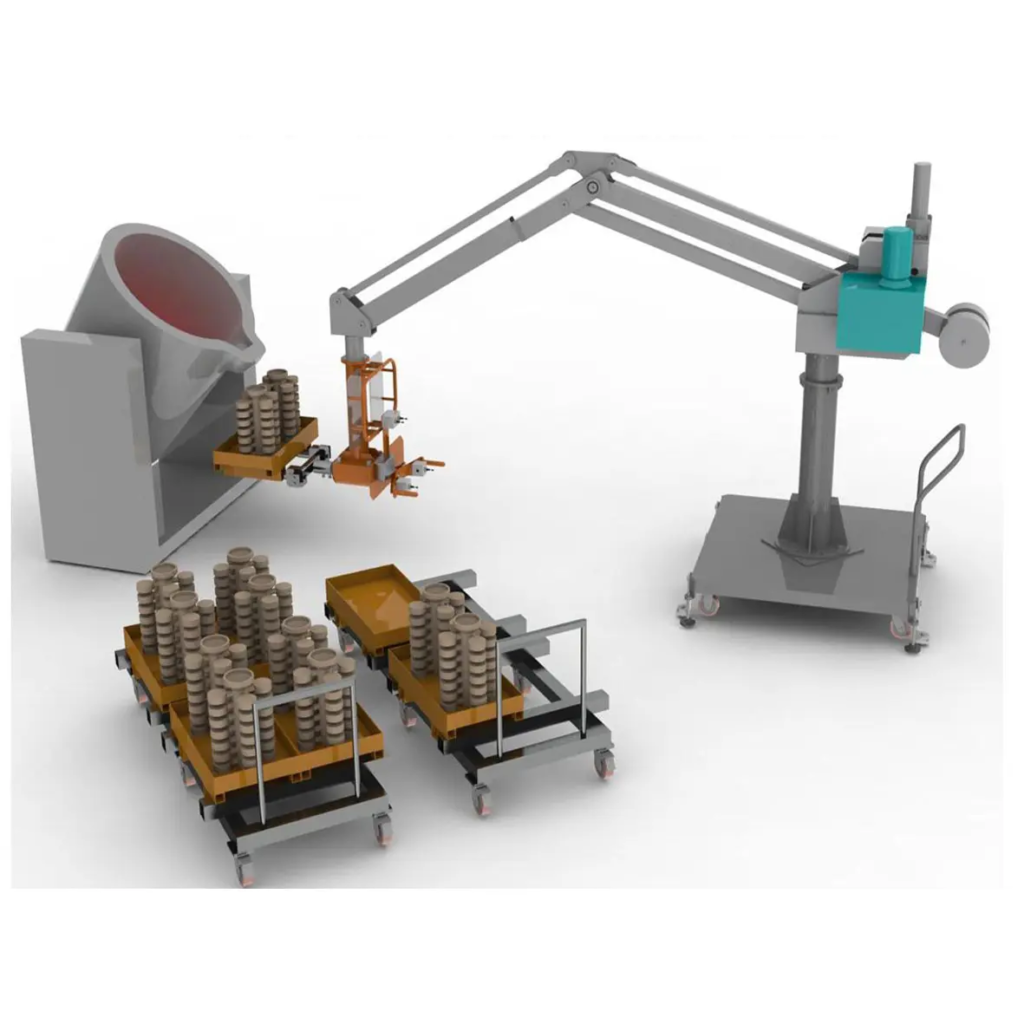

- Smart Automation: AI-driven robotics reduce labor costs by 40% and defects by 30%.

B. Global Compliance & Certifications

- Quality Assurance: CE, RoHS, and UL certifications ensure compliance in 30+ countries.

- Industry-Specific Standards: AS9100 (aerospace), IATF 16949 (automotive), ISO 13485 (medical).

C. Cost Efficiency

- Direct Factory Pricing: 25–40% lower CAPEX vs. Western suppliers.

- Scalable Models: Modular systems adapt from prototypes to mass production.

Related Keywords: precision casting equipment supplier, global foundry solutions

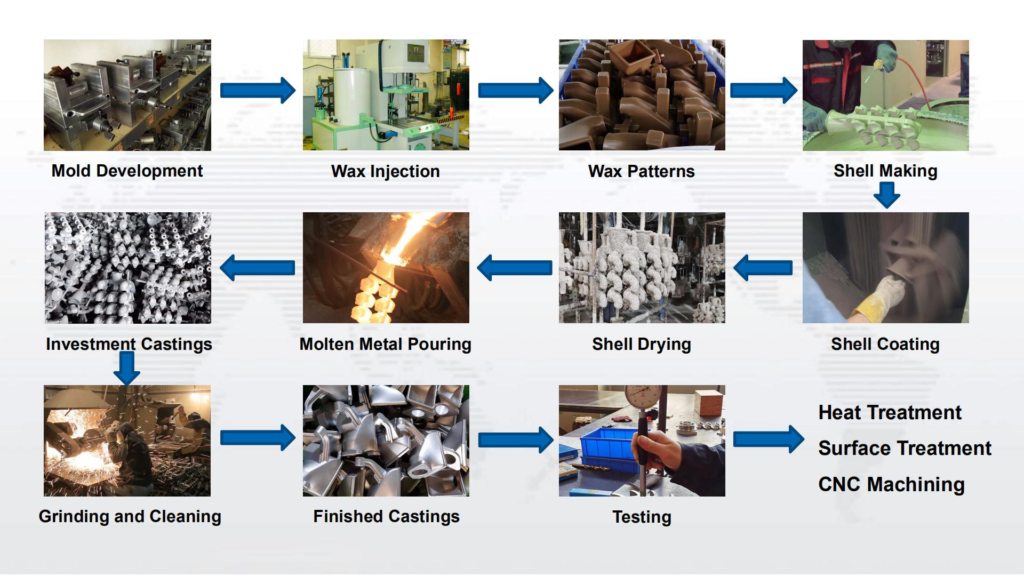

2. Core Investment Casting Equipments Supplier Offered by KEWEI

A. Wax & Pattern Systems

- 3D Wax Printers: ±0.05mm accuracy for complex geometries.

- Automated Wax Injectors: AI optimizes temperature/pressure for zero-defect patterns.

B. Ceramic Shell Equipment

- Robotic Slurry Coaters: 6-axis arms ensure ±0.1mm shell uniformity.

- Eco-Friendly Materials: Low-VOC binders and 100% recyclable shells.

C. Melting & Pouring Technology

- Vacuum Induction Furnaces: Melt superalloys up to 1800°C (±3°C stability).

- IoT Pouring Robots: Adaptive flow control eliminates turbulence defects.

D. Post-Casting Solutions

- Automated Knockout Machines: 50% faster shell removal.

- 5-Axis CNC Machines: Achieve Ra <0.8μm for medical implants.

Related Keywords: investment casting machinery supplier, industrial foundry equipment

3. Industry Success Stories

Aerospace: Turbine Blade Production

- Challenge: A U.S. aerospace OEM needed AS9100-certified equipment for Inconel 718 turbine blades.

- Solution: KEWEI supplied vacuum furnaces + 7-axis CNC machines.

- Result: 99.9% defect-free rate and 25% faster cycle time.

Medical: Titanium Implant Manufacturing

- Challenge: A European client required FDA-compliant finishing systems.

- Solution: Cleanroom-grade CNC equipment with Ra <0.4μm capability.

- Result: Reduced post-processing costs by 35%.

Related Keywords: aerospace casting supplier, medical-grade foundry equipment

4. KEWEI’s Supplier Advantages

- Global Logistics Network: DDP (Delivered Duty Paid) shipping to 30+ countries.

- 24/7 Technical Support: Remote diagnostics + on-site engineers in 15 regions.

- Custom Financing: Leasing plans from $1,500/month for flexible CAPEX.

Related Keywords: reliable foundry equipment supplier, certified casting machinery

5. Partnering with KEWEI: Simple & Transparent

- Free Audit: Submit your requirements for a tailored equipment proposal.

- Risk-Free Trial: Test machines with a 30-day satisfaction guarantee.

- Lifetime Upgrades: Access AI-driven software updates at no extra cost.

Request a Custom Quote Within 24 Hours!