KEWEI Investment Casting Equipments Factory

Global Leader in Precision Foundry Solutions

Introduction

In an era where precision and efficiency define manufacturing success, the investment casting equipments factory you choose becomes a strategic partner in your growth. KEWEI, a global ISO 9001 and AS9100-certified factory, stands as a leader in designing, manufacturing, and delivering end-to-end investment casting equipment trusted by aerospace, automotive, and medical industries. With 20+ years of expertise, vertically integrated production, and smart automation, discover why OEMs across 30+ countries rely on KEWEI’s “Made-in-China” excellence.

1. Why Choose KEWEI as Your Equipment Factory?

KEWEI’s investment casting equipment factory offers unmatched advantages:

- Cost Efficiency: 20-30% lower CAPEX vs. Western suppliers, with equal or superior quality.

- Scalable Production: Manufacture 500+ machines/year for bulk global orders.

- R&D Leadership: 15% annual revenue reinvested in AI-driven automation and material science.

- Global Compliance: CE, UL, and RoHS certifications for seamless export.

Related Keywords: investment casting machinery factory, china foundry equipment supplier

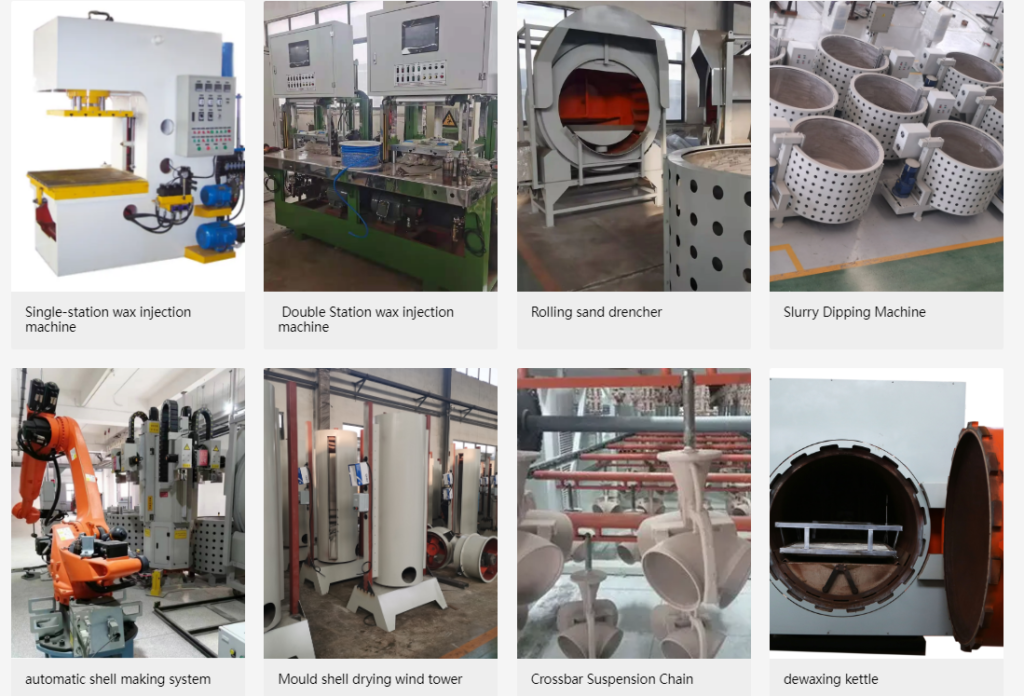

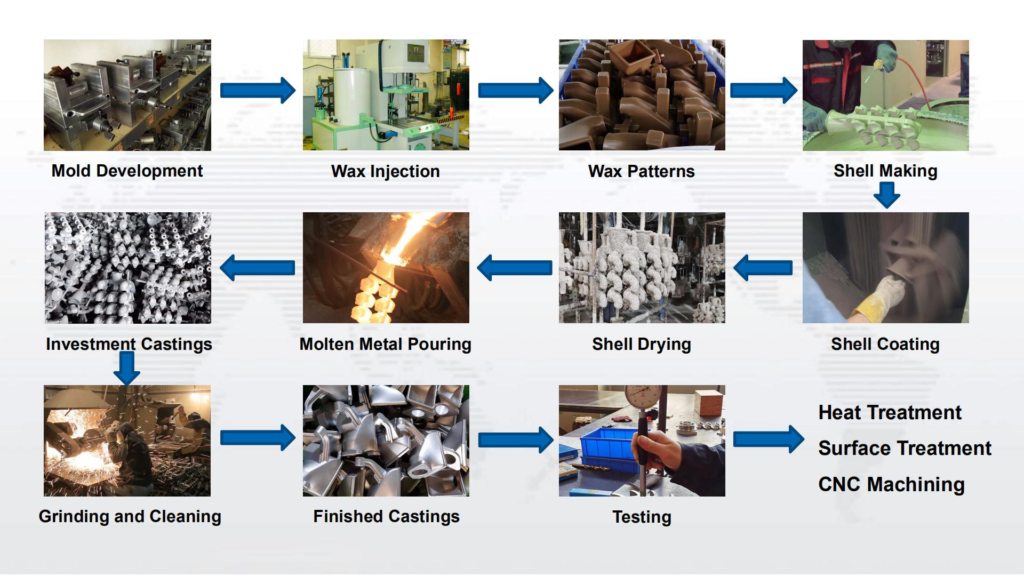

2. Core Equipment from KEWEI Factory

KEWEI’s factory produces the full spectrum of investment casting equipment:

A. Wax & Pattern Systems

- 3D Wax Printers: ±0.05mm accuracy for complex geometries.

- AI-Controlled Wax Injectors: Reduce defects by 35% via real-time parameter adjustment.

B. Ceramic Shell Solutions

- Robotic Slurry Coaters: 6-axis arms ensure ±0.1mm shell uniformity.

- Fluidized Bed Stucco Units: Optimized for zirconia-alumina blends.

C. Melting & Pouring Technology

- Vacuum Induction Furnaces: Melt superalloys up to 1800°C (±3°C stability).

- IoT-Enabled Tilt Pourers: Prevent turbulence defects in thin-wall castings.

D. Post-Casting Equipment

- Automated Knockout Machines: 50% faster shell removal with <0.1% part damage.

- 5-Axis CNC Finishers: Achieve Ra <0.8μm for medical/aerospace components.

Related Keywords: precision casting machinery, foundry equipment manufacturer

3. KEWEI’s Factory Capabilities: Innovation at Scale

- Smart Manufacturing Hub: IoT-enabled production lines with real-time quality tracking.

- Material Science Lab: Develop proprietary alloys and ceramic shell blends.

- Global Logistics Network: 15-day lead time for standard equipment, air/sea freight options.

Case Study: A U.S. aerospace supplier cut equipment costs by 28% and downtime by 40% sourcing from KEWEI’s factory.

Related Keywords: industrial casting equipment factory, automated foundry systems

4. Industry-Specific Solutions

KEWEI tailors equipment for mission-critical applications:

- Aerospace: Vacuum furnaces + 7-axis CNC machines for NASA-spec turbine blades.

- Medical: Cleanroom-compatible 3D wax printers (ISO 13485 certified).

- Energy: High-pressure shell systems for API 6A valve production.

Related Keywords: custom foundry equipment, investment casting plant solutions

5. Partnering with KEWEI: Beyond Equipment Supply

Choosing KEWEI’s factory unlocks:

- Free Process Audit: Optimize your workflow with KEWEI engineers.

- Turnkey Projects: From factory layout design to staff training.

- Lifetime Support: Predictive maintenance via AI and global spare parts hubs.

Related Keywords: investment casting equipment supplier, turnkey foundry builder

Conclusion

A KEWEI investment casting equipment factory is more than a manufacturer—it’s a gateway to precision, scalability, and global competitiveness. With 50+ patents, 20+ years of cross-industry expertise, and a client-centric approach, KEWEI empowers foundries to transform raw materials into high-value components faster, smarter, and greener.

Ready to Equip Your Success?

Visit KEWEI Factory or Request a Virtual Tour Today!