Equipment Needed for Investment Casting

Your Partner for Precision and Efficiency

Investment casting, also known as lost-wax casting, is a precision manufacturing process used to create complex metal parts. To achieve high-quality results, right equipment is needed for investment casting. At KEWEI, we specialize in providing state-of-the-art machines and tools for every step of the investment casting process.

Core Equipment for Investment Casting

- Wax Injection Machines

- Function: Produce precise wax patterns for casting.

- Key Features: Temperature control, multi-cavity molds, high-speed cycling.

- Why Choose KEWEI: Our wax injectors are designed for high precision and durability, ensuring flawless wax patterns every time.

- Ceramic Shell Coating Systems

- Function: Apply ceramic layers to wax patterns.

- Key Features: Robotic arms, adjustable slurry viscosity, drying chambers.

- Why Choose KEWEI: KEWEI’s coating systems deliver uniform ceramic shells, reducing defects and improving casting quality.

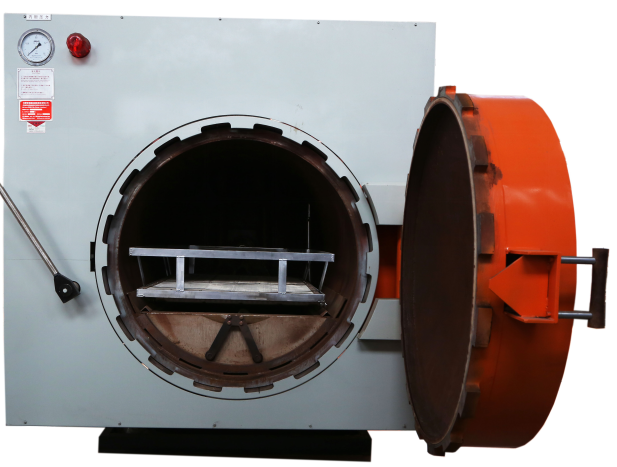

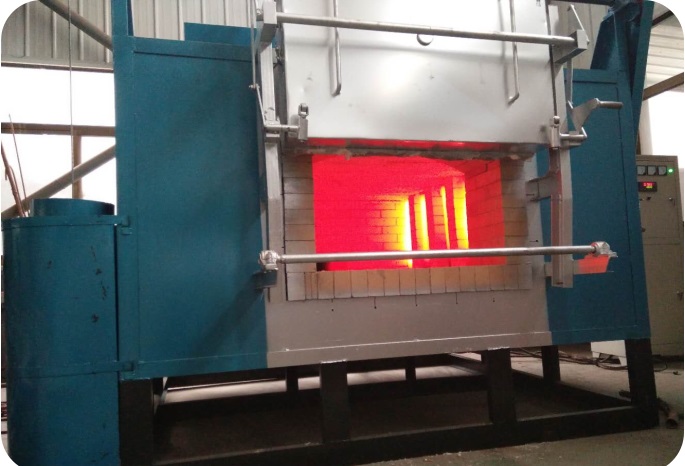

- Dewaxing & Sintering Furnaces

- Function: Remove wax and harden ceramic shells.

- Key Features: High-temperature capability, energy efficiency, vacuum options.

- Why Choose KEWEI: Our furnaces are engineered for optimal energy use and consistent performance, even in high-volume production.

- Vacuum Casting Units

- Function: Pour molten metal into ceramic molds under vacuum.

- Key Features: Porosity-free casting, precise temperature control.

- Why Choose KEWEI: KEWEI’s vacuum casting units ensure defect-free castings, ideal for aerospace and medical applications.

- Cooling & Shell Removal Systems

- Function: Cool castings and remove ceramic shells.

- Key Features: Water jets, vibration tables, automated handling.

- Why Choose KEWEI: Our systems are designed for efficient cooling and easy shell removal, minimizing downtime.

Auxiliary Equipment for Investment Casting

- Melting Furnaces: Melt metal alloys (e.g., stainless steel, titanium).

- Robotic Arms: Automate wax assembly, coating, and part handling.

- Quality Control Tools: X-ray machines, CMMs for defect detection.

- Environmental Systems: Dust collectors, fume extractors for safety.

Why Choose KEWEI: We offer a complete range of auxiliary equipment to streamline your investment casting process, from melting to quality control.

How to Choose the Right Casting Equipment

- Define Your Needs: Consider part size, material, and production volume.

- Evaluate Suppliers: Look for ISO-certified manufacturers like KEWEI with proven track records.

- Budget Planning: Balance upfront costs with long-term ROI.

- After-Sales Support: Ensure training, maintenance, and spare parts availability.

Why Choose KEWEI: Our team provides personalized consultations to help you select the best equipment for your needs, backed by comprehensive after-sales support.

Benefits of Modern Investment Casting Equipment

- High Precision: Achieve tolerances as tight as ±0.1mm.

- Material Versatility: Cast stainless steel, aluminum, superalloys, and more.

- Cost Efficiency: Reduce waste and post-processing with advanced automation.

- Scalability: From prototyping to mass production, meet any demand.

Why Choose KEWEI: Our equipment is designed to deliver these benefits, ensuring your foundry operates at peak efficiency.

FAQs About Investment Casting Equipment

Q: What’s the difference between manual and automated machines?

A: Manual machines are cheaper but slower; automated systems offer higher efficiency and precision. KEWEI provides both options to suit your budget and production needs.

Q: Can one machine handle multiple materials?

A: Some machines are versatile, but specialized equipment often delivers better results. KEWEI offers customizable solutions for multi-material casting.

Q: How do I know if a supplier is reliable?

A: Check certifications (ISO 9001), customer reviews, and after-sales support. KEWEI is a trusted name in the industry, with a global reputation for quality and service.

Ready to Upgrade Your Investment Casting Process with KEWEI?

✅ Free Consultation: Get expert advice tailored to your needs.

✅ Competitive Quotes: Compare prices from top suppliers.

✅ Fast Delivery: Minimize downtime with quick shipping.