KEWEI Equipment for Lost Wax Casting

Precision Tools for Next-Gen Manufacturing

Introduction

In the high-stakes realm of investment casting, the right Equipment for lost wax Casting—from melting furnaces to robotic finishing systems—determines product quality, operational efficiency, and profitability. KEWEI, a global ISO 9001-certified manufacturer, delivers end-to-end investment casting equipment trusted by aerospace, automotive, and medical industries. Discover how KEWEI’s integrated solutions combine German engineering precision with scalable “Made-in-China” value to future-proof your foundry.

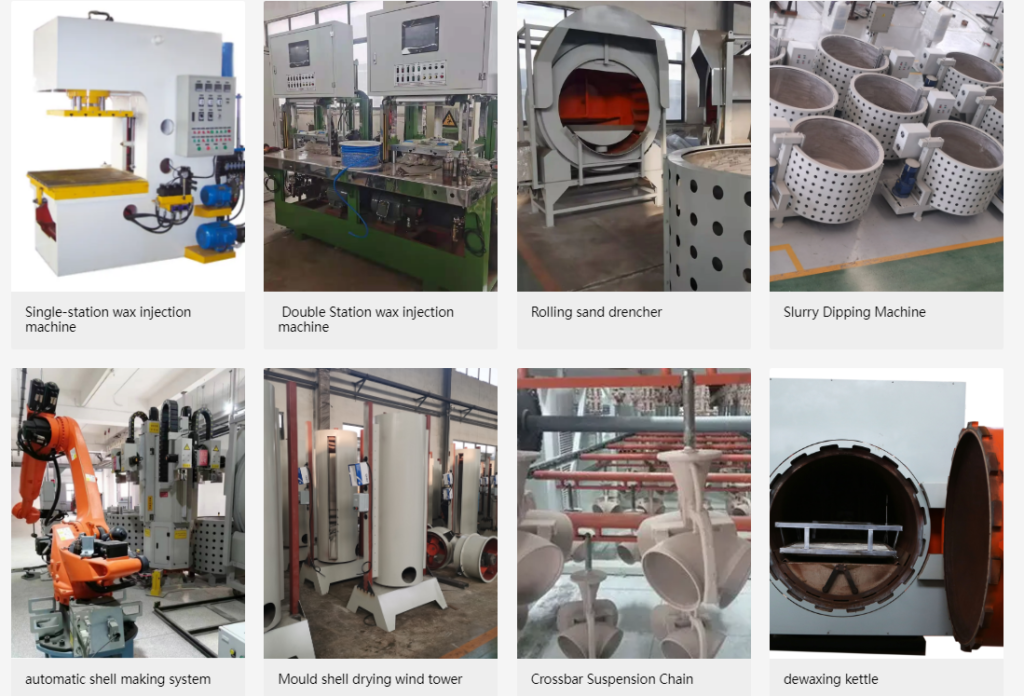

1. Core Equipment for lost wax Casting: KEWEI’s Ecosystem

KEWEI’s investment casting equipment portfolio covers every production stage:

A. Melting & Pouring Systems

- Vacuum Induction Furnaces: Melt superalloys (e.g., Inconel 718) up to 1800°C with ±5°C accuracy.

- Robotic Tilt Pourers: 6-axis robots ensure laminar flow for defect-free thin-wall castings.

B. Mold-Making Solutions

- Automated Shell Coating Lines: AI-guided slurry application with 0.1mm uniformity.

- 3D-Printed Wax Pattern Machines: Achieve ±0.05mm tolerances for complex geometries.

C. Post-Casting Equipment

- Shot Blasting Machines: Remove ceramic shell residues 50% faster.

- CNC Deburring Robots: Force-controlled tools for medical-grade surface finishes.

Related Keywords: investment casting machinery, foundry equipment solutions

2. Why KEWEI Equipment Outperforms Competitors

KEWEI’s equipment for investment casting solves critical industry pain points:

- Energy Savings: Patented insulation cuts furnace power consumption by 25%.

- Zero Downtime: IoT-enabled predictive maintenance alerts prevent unplanned stops.

- Scalability: Modular designs adapt from prototyping to mass production.

Case Study: A Tier-1 automotive supplier reduced per-unit costs by 18% using KEWEI’s integrated wax injection and shell coating line.

Related Keywords: KEWEI foundry equipment, automated casting machinery

3. Industry-Specific Equipment Configurations

KEWEI tailors systems to meet stringent requirements:

- Aerospace: Vacuum furnaces + robotic pourers for turbine blades (AMS 2175/AMS 2750).

- Medical: Cleanroom-compatible 3D wax printers + electropolishing systems (ISO 13485).

- Energy: High-capacity melting furnaces for corrosion-resistant valve production.

Related Keywords: custom investment casting equipment, industrial foundry machinery

4. Overcoming Foundry Equipment Challenges

- High Labor Costs? KEWEI’s robotic cells reduce manual labor by 60%.

- Inconsistent Quality? Machine learning optimizes process parameters in real-time.

- Slow ROI? Achieve breakeven in <14 months via waste reduction and uptime gains.

Related Keywords: investment casting automation, foundry equipment ROI

5. Partnering with KEWEI: Beyond Hardware

Choosing KEWEI unlocks comprehensive support:

- Free Facility Layout Design: Optimize equipment placement for maximum throughput.

- Smart Factory Integration: Sync equipment with ERP/MES via OPC-UA protocols.

- Global Compliance: CE, UL, and ASME certifications for hassle-free export.

Related Keywords: investment casting equipment supplier, turnkey foundry solutions

Conclusion

In an era where precision and agility define manufacturing success, KEWEI equipment for investment casting delivers the technological edge to dominate global markets. With 15+ years of innovation, vertically integrated production, and a client-first ethos, KEWEI empowers foundries to achieve zero-defect production, slash costs, and embrace Industry 4.0. Ready to Equip Your Future? Download KEWEI’s Full Equipment Catalog or Schedule a Virtual Demo Today!