KEWEI Investment Casting Equipments China

Precision, Cost-Efficiency & Global Compliance

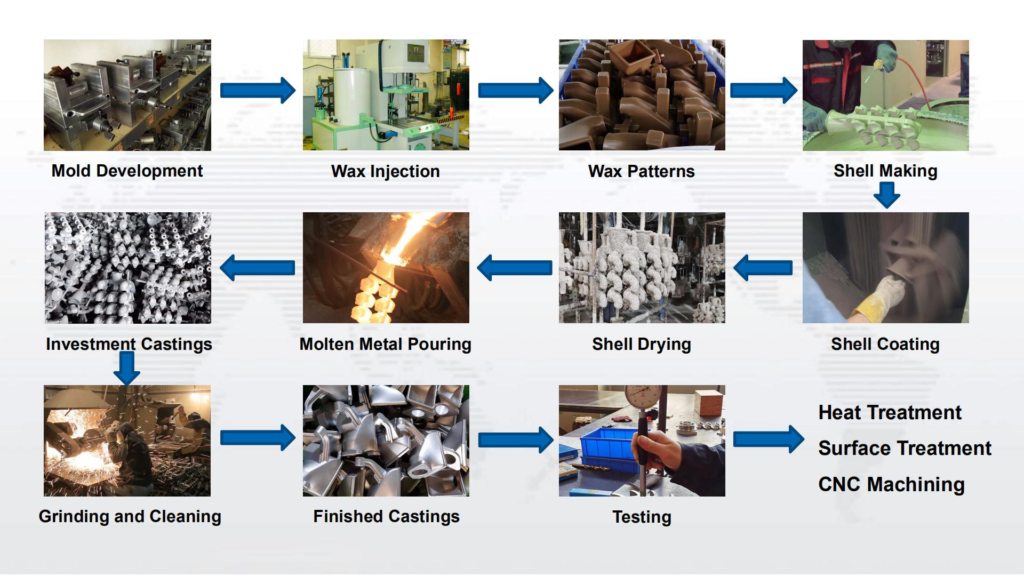

As global industries seek to balance precision and cost-efficiency, Investment Casting Equipments China has emerged as a cornerstone of modern manufacturing. KEWEI, a leading ISO 9001 and AS9100-certified Chinese manufacturer, delivers investment casting equipment that combines German-engineered accuracy with “Made-in-China” value. Trusted by aerospace, automotive, and medical sectors worldwide, KEWEI empowers foundries to achieve zero-defect production, 30% lower operational costs, and rapid scalability. Discover why global OEMs choose China’s KEWEI as their strategic partner.

1. Why Source Investment Casting Equipments from China?

China’s manufacturing ecosystem offers unparalleled advantages for foundry equipment:

- Cost Efficiency: 20-40% lower CAPEX vs. Western suppliers, without compromising quality.

- Supply Chain Mastery: Local access to high-purity alloys, ceramics, and automation components.

- Scalability: Produce 500+ machines/year for bulk orders with 15-day lead times.

KEWEI’s Edge: As a Top 10 Chinese Foundry Equipment Exporter, we integrate these strengths with cutting-edge R&D and global compliance.

Related Keywords: china foundry equipment supplier, investment casting machinery china

2. KEWEI’s Core Equipment: Technology-Driven Excellence

KEWEI’s investment casting equipment redefines industry standards:

- Smart Wax Systems: AI-controlled 3D wax printers achieve ±0.05mm tolerances.

- Robotic Shell Coating: 6-axis arms ensure ceramic shell uniformity (±0.1mm).

- Energy-Efficient Furnaces: Vacuum induction melters reduce power use by 25% vs. competitors.

- 5-Axis CNC Finishers: Achieve Ra <0.8μm for medical/aerospace components.

Case Study: A German automotive supplier cut equipment costs by 35% sourcing KEWEI’s China-made robotic pouring systems for aluminum EV parts.

Related Keywords: china casting machinery, precision foundry equipment

3. Industry-Specific Solutions Investment Casting Equipments China

KEWEI tailors equipment for global standards:

- Aerospace: AS9100-compliant vacuum furnaces + CNC machines for turbine blades.

- Medical: ISO 13485-certified cleanroom systems for titanium implants.

- Energy: API 6A-approved high-pressure shell systems for valves.

Related Keywords: industrial casting equipment china, custom foundry solutions

4. Overcoming Global Buyers’ Concerns

- Quality Assurance? KEWEI’s equipment meets CE, RoHS, and UL certifications.

- IP Protection? NDAs and secure data protocols ensure design confidentiality.

- Logistics Risks? Air/sea freight with MIL-SPEC packaging and real-time tracking.

Related Keywords: reliable china casting equipment, secure manufacturing partnerships

5. Partnering with KEWEI China: End-to-End Support

Choosing KEWEI unlocks:

- Free ROI Analysis: Compare total ownership costs vs. Western suppliers.

- Turnkey Solutions: From equipment installation to operator training.

- 24/7 Global Support: Remote diagnostics + regional spare parts hubs.

Related Keywords: china investment casting equipment supplier, turnkey foundry builder

Conclusion

In a competitive global market, KEWEI investment casting equipment China delivers the precision, scalability, and cost-efficiency that define manufacturing success. With 20+ years of expertise, 50+ patents, and a client base across 30 countries, KEWEI is China’s gateway to world-class foundry solutions.

Ready to Leverage China’s Manufacturing Power?

Contact KEWEI for a Customized Quote or Schedule a Factory Tour!